Evolutionary

Shape Optimisation

Using a Voxel

Based Representation.

Peter James

Baron

MSc

Information Technology: Knowledge Based Systems

Department of

Artificial Intelligence

University of

Edinburgh

1997

Abstract

Shape optimisation within

constraint limits is a hard problem from the field of Mechanical

Engineering. The objective is to design

a shape which best satisfies some predetermined goal whilst at the same time

observing some constraints. Much work

has been done on various problems within this domain [Bentley 96][Chapman et al. 94] [Smith 95a][Watabe &

Okino 93], however the majority to-date has focused on parametric and other

highly restricted representations of the shapes being optimised. This thesis describes experiments performed

using a voxel based representation and an evolutionary optimisation

algorithm. As any attempt to perform

shape optimisation using an unrestricted object representation must use a highly

effective evaluation function in order to be able to deal with the varieties of

design that an evolutionary optimisation algorithm may produce, the work

detailed here was intended to first design and test suitable operators to deal

with the extremely large chromosomes required by a voxel representation, and by

then extending the work to permit evaluation from a commercial Finite Element

analysis package, it was expected that the program would be able to perform

real-world shape optimisation tasks with very few restrictions on the shapes

being tested. The results obtained

indicate that it is possible to circumvent the difficulties presented by a

voxel representation [Watabe & Okino 93], and that with suitable operators,

useful and unexpected results can be gained from a real-world optimisation task.

Acknowledgements

I would like to thank my primary supervisor

Dr. R. Fisher for his guidance, advice and assistance throughout all of the

stages of this project. I would also

like to thank Dr. F. Mills of the Department of Mechanical Engineering for his

assistance with the Mechanical Engineering side of things, and Andy Sherlock at

the Department of Mechanical Engineering for his invaluable advice and his

willingness to help with any and all aspects of the project.

During the past three years Andrew Tucson has been

an invaluable source of useful knowledge, good advice and friendship, and for

these gifts I wish to express my sincere appreciation.

Finally I want to thank Julie Humphrey who has

constantly reassured me that the effort is worthwhile and without whom it might

not have been.

Contents

1 Introduction

1

1.1 Introduction to the problem . . . . . . . . . . . . . . . .

1

1.2 Approach taken . . . . . . . . . . . . . . . . . . . .

2

1.3 Contributions made by this work . . . . . . . . . . . . . .

5

1.4 Outline of this thesis . . . . . . . . . . . . . . . . . .

5

2 Background and previous work 8

2.1 The

problems to be addressed . . . . . . . . . . . . . . .

8

2.2 The genetic algorithm . . . . . . . . . . . . . . . . . 11

2.2.1 Other search techniques . . . . . . . . . . . . . . . 12

2.2.2 Advantages of the genetic algorithm . . . . . . . . . . . 15

2.2.3 The standard genetic algorithm . . . . . . . . . . . . . 16

2.3 Introduction to shape optimisation . . . . . . . . . . . . . 19

2.3.1 The stress analysis model mathematics . . . . . . . . . . 20

2.3.2 Possible approaches to shape optimisation . . . . . . . . . 21

2.3.3 The voxel based approach to shape optimisation . . . . . . . 22

2.4 Miscellaneous relevant work on GA based

shape optimisation . . . 24

2.5 Conclusions . . . . . . . . . . . . . . . . . . . . 25

3 Design and testing of new operators 27

3.1 The

one-dimensional experiments . . . . . . . . . . . . . 27

3.2 A two-dimensional representation of a beam

cross-section . . . . . 31

3.3 The GA experiments . . . . . . . . . . . . . . . . . 32

3.3.1 Experiments using the naïve GA . . . . . . . . . . . . 33

3.3.2 Results obtained from the naïve GA . . . . . . . . . . . 33

3.3.3 Experiments with the rank selection pressure . . . . . . . . 36

3.3.4 Experiments with the constraint penalty

multiplier . . . . . . 40

3.3.5 Experiments with a dynamically changing

constraint penalty

multiplier . . . . . . . . . . . . . . . . . 46

3.3.6 A new operator: smoothing . . . . . . . . . . . . . . 53

3.3.7 An n-dimensional crossover operator . . . . . . . . . . . 56

3.3.8 An n-dimensional mutation operator . . . . . . . . . . . 60

3.3.9 Dynamic mutation operator probabilities . . . . . . . . . . 63

3.3.10 Comparison of modified GA with naïve GA . . . . . . . . 66

3.4 Conclusions about the simplified physics

model experiments . . . . 68

4 Transferring the solutions to real problems 71

4.1 Motivation

for this approach . . . . . . . . . . . . . . . 71

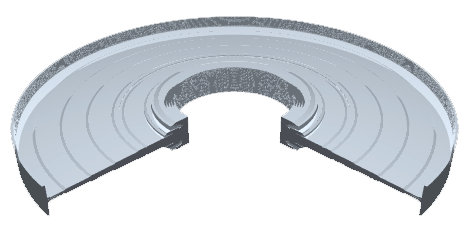

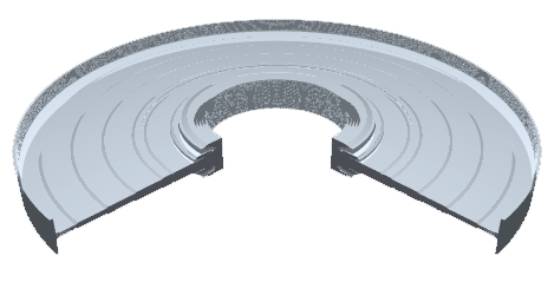

4.2 The annulus design problem . . . . . . . . . . . . . . . 72

4.3 Implementation details . . . . . . . . . . . . . . . . . 73

4.4 Results from the basic system . . . . . . . . . . . . . . 77

4.5 Improvements made to the system . . . . . . . . . . . . . 82

4.6 Conclusions about the real-world system . . . . . . . . . . . 90

5 Conclusion

92

5.1 Summary

of conclusions . . . . . . . . . . . . . . . . 92

5.2 Further work . . . . . . . . . . . . . . . . . . . . 94

Appendices 95

A Rolls Royce annulus problem specification 95

B Ansys macro listings 99

B.1 Full

optimisation macro mask listing . . . . . . . . . . . . 99

B.2 Single optimisation macro listing . . . . . . . . . . . . .

109

C Results log files 110

C.1 Log of

basic GA results on annulus problem . . . . . . . . . .

110

C.2 Log of improved GA results on annulus problem . . . . . . . . 116

Bibliography 123

Chapter One.

Evolutionary Shape Optimisation Using a Voxel Based

Representation.

1.1

Introduction to the problem.

Shape

optimisation is the process of attempting to discover the optimum shape to

perform some given task, frequently within some pre-determined

constraints. In some simple cases the

solution may be readily apparent, even trivial, for example; to maximise volume

and minimise surface area the shape required is a sphere. However in most cases the solution is not so

easily found. Engineering knowledge and

a sound understanding of the underlying physics of a problem may enable a

well-trained person to make a good guess as to a suitable form, but this leaves

open the possibility of major improvements being totally overlooked and may not

be sufficient if the problem being addressed is very highly constrained.

This thesis examines two

different shape optimisation problems and will attempt to show that the

combination of genetic algorithms with suitable operators and a voxel based

representation, forms an effective tool for solving this type of problem.

The first optimisation

addressed in this thesis is that of minimising the amount of mass in

load-bearing beams, whilst ensuring that the maximum stress they are capable of

withstanding remains above a given minimum level. This is tackled first by means of a mathematical model which

contains some simplifying assumptions about the physics of the situation. Although this is not very realistic in terms

of a real-world analysis, it has the advantage of being very quick to run which

makes it a suitable test-bed for experimentation with the operators and the

parameters of the GA being used.

The second optimisation is

that of designing a minimum mass annulus for a jet-turbine engine which must

withstand several different forces without exceeding the maximum stress limits

in any one of several key areas. This

problem does not have any simplifying assumptions, and so is analysed in full

by a commercial Finite Element analysis package; Ansys 5.3*

. As the evaluation function is very

time-consuming it was necessary to design several new GA operators which

increase the rate of improvement considerably.

Previous work in this field includes:

n

[Bentley

96] which has successfully evolved a wide range of shapes and structures using

geometric primitives as building blocks.

n

[Chapman

et al. 94] which addresses issues in

structural topology design using pixels as design primitives with a standard

GA.

n

[R

Smith 95a] which uses a GA with a parametric representation to optimise the

same annulus problem covered in Chapter 4 of this thesis.

A more detailed description of shape optimisation

and stress analysis will be presented in Chapter Two.

1.2 Approach

taken.

The representation of the

problem space chosen for this work is that of voxels+

, which are a method of partitioning the search area or volume into rectangular

regions or boxes which are then assigned a binary full/empty value.

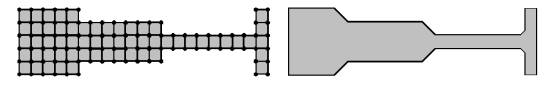

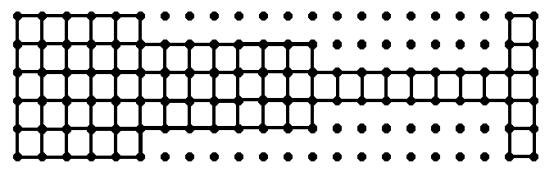

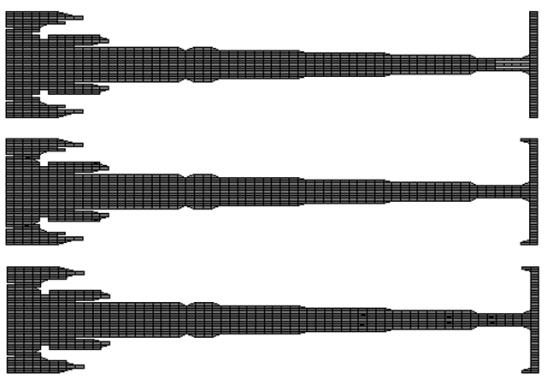

A Voxel Representation of a Part. The Original Part.

Figure 1.1

This approach has many advantages over the

alternatives including:

n

The

ability to represent any shape without restriction.

n

The

ease with which an existing engineering solution can be converted into voxels.

n

A

natural mapping to the traditional binary chromosomal representation frequently

used by GAs.

n

The

simplicity with which domain knowledge can be integrated into the solution.

However in

[Watabe & Okino 93] the authors object that voxels suffer from several

apparently fatal weaknesses when used to represent this type of problem

including:

n

The

occurrence of small holes in the final shape.

n

The

long length of the chromosomes.

n

The

expectation that cross-over would be ineffective.

n

The

lack of smoothness in the final shape’s outline.

It will be

shown during the early experiments described in Chapter 3 that these objections

do not constitute a problem when addressed with appropriate operators and GA

optimisations.

The choice

of voxels as a representational form was motivated by several key points. The previous work which has made use of

voxels has tended to either avoid using domain knowledge in the operator

design, or has concentrated on very low resolution voxel grids in an attempt to

avoid huge chromosomes. Voxels also

offer some important advantages over other representations, including the

ability to generate unexpected designs, the ease with which the user can initialise

the population to the previous best solution and quick incorporation of domain

knowledge in the form of areas of voxels with fixed values.

Genetic Algorithms (GAs)

have proven themselves to be a highly flexible search technique, able to find

good solutions to a diverse range of problems in many different fields

[Goldberg 89]. They use evolutionary

computation techniques to search large and difficult fitness landscapes in

order to find near-optimal solution vectors.

[Michalewicz 92] describes

“evolution programs” as a sub-class of the range of algorithms which rely on

analogies to natural processes. In

[Michalewicz 92] he writes:

“… a population of individuals (potential solutions) … undergoes a

sequence of unary … and higher order … transformations. These individuals strive for survival: a

selection scheme biased towards fitter individuals selects the next

generation. After some number of

generations, the program converges - the best individual hopefully represents

the optimum solution.”.

In this thesis the term GA

will be substituted for Michalewicz’s “evolution programs” to reflect the fact,

widely recognised in the field of evolutionary computation, that the original

definition of GA (as using only binary chromosomes, simple crossover and

bitwise mutation) is far too narrow and explicit to encompass this rapidly

growing field.

As the nature of the voxel

representation leads inevitably to extremely large search areas the use of GAs

is an obvious choice. A further

introduction to the theory of GAs can be found along with a more detailed description

of shape optimisation, stress analysis and the voxel based representation in

Chapter 2.

1.3 Contributions made by this work.

During the

first set of experiments a number of new and modified operators were designed

and tested, and some of them proved to be extremely effective at reducing the

amount of time taken for the GA to achieve a good solution. Several other operators were found which

directly address the issues raised by [Watabe & Okino 93] and solve the

problems described by them.

The second set of

experiments extends the range of previous work in this domain to use a

commercial FE package to perform the optimisation. Two sets of experiments were performed, firstly a simple

adaptation of the GA to the new problem was tested. Although these experiments did discover some difficulties when

using Finite Element Analysis with a voxel based representation, further work

resulted in the design of a set of solutions to those difficulties and some

very interesting results were obtained from the analysis.

The work

in this thesis will show that a genetic algorithm using a voxel based

representation, whilst suffering from several difficulties, is by no means an

implausible approach to the problem of shape optimisation. The benefits obtained by using this

representation may in many cases out-weigh the disadvantages, thus making it an

appropriate technique for optimisations where the optimum is unknown or where

engineering insights are to be used to assist the process.

1.4 Outline of

this Thesis.

The task was addressed as a

series of experiments, each of which built on the results of the previous

steps; the format of this thesis reflects this approach, with the majority of

the work being presented in the order of experimentation and with appropriate

comments where one set of experiments suggested the approach to be taken next.

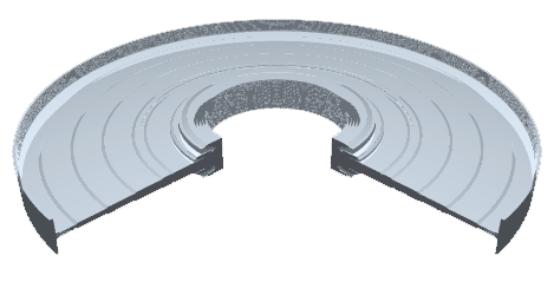

Final Annulus Design from the Results Set.

Figure 1.2

The majority of Chapter 2

deals with the background explanations of GAs, shape optimisation and stress

analysis necessary to understand the rest of the thesis. An investigation was then made into the

current state of the art in shape optimisation, with particular reference to

the use of GAs to perform the search.

The results of this study are presented in Section 2.3.

Initially, a two dimensional

shape optimisation problem was undertaken using simplifying assumptions in the

stress analysis model. This allowed

rapid evaluations of the shapes produced by the GA, thus permitting in-depth

investigation into the effectiveness of various modifications to the basic

optimisation technique. A description

of these experiments, their results, and the optimisations made can be found in

Chapter 3.

Once the GA code was running

effectively on this simplified problem, the level of realism in the stress

analysis model was increased by using a commercial Finite Element package to

perform the shape evaluation. At this

point the experiments were using a realistic representation of all stresses

involved in the shapes generated by the GA.

Chapter 4 gives details of the approach taken, the results and the

difficulties encountered during this final stage of the experimentation.

Chapter 5

contains the conclusions arrived at during this study and the recommendations for future work.

The

Appendices include details of the annulus design problem specification, the

macros uses to make Ansys perform the optimisation and some results data files.

Chapter Two.

Background and Previous Work:

2.1 The problems to be addressed.

The first

optimisation addressed in this thesis is the design of a beam cross-section

which minimises the amount of material in the beam, whilst leaving it capable

of supporting a given minimum mass.

This problem will be approached using a simplified model of the physics

involved in order that the speed of evaluation is as fast as possible. The second optimisation is the design of an

annulus for the centre of a jet-engine’s turbine propeller, which must be as

light as possible but still be able to withstand stresses in two different

directions at various key positions.

This will be evaluated using a full commercial Finite Element Analysis

(FEA) package in order that all of the forces and stresses experienced by the

part are simulated as accurately as possible.

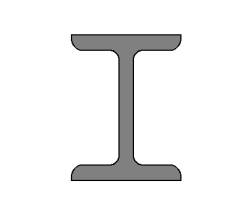

The beam

optimisation was chosen as an example of a sufficiently hard problem that, even

when using a simplified model of the physics involved, the solution surface

would be extremely complex. An

additional reason for the choice of this problem is that a good solution is

well-known to engineers. The ‘I’ beam

(shown in Figure 2.1), which is commonly used in sky-scraper construction, is

generally accepted as being a good form for a beam cross-section to gain

maximum strength for minimal mass.

Issues to be addressed in this optimisation were;

n

How

well does a standard GA perform on a complicated problem using a voxel

representation?

n

Can

operators be designed that overcome any perceived flaws in the standard GA?

n

What

alternative operators can be designed to improve the GA performance in regards

to voxel based optimisations?

n

What

adjustments should be made to the balance of operators to further increase the

rate of optimisation?

An ‘I’ Beam Cross-Section.

Figure 2.1

The

annulus design problem is specified in detail in a document supplied by Rolls

Royce to Richard Smith during his time with the Mechanical Engineering

department of Edinburgh University, which is included as Appendix A. As specified by Rolls Royce, the annulus

design is very tightly constrained, ie: the figures given for maximum stress

represent a reasonably good solution.

This was expected to cause some difficulties as a random population

initialisation would probably create an initial population which contains only

invalid solutions.

The choice

of a voxel based representation was expected to raise some difficulties when

the solutions produced were analysed by the FE package. This is because FEA does not cope well with

sharp corners and will normally not use uniformly sized meshes. Voxels are by definition uniform in size,

and though it would in theory be possible to subdivide edge voxels into a finer

grid, the FE package used for this analysis (Ansys v5.3) could only recognise

elements which connect at their major vertices. Thus in order to subdivide the voxels into a finer grained mesh

would involve at least one intermediate step and a lot of extra processing, as

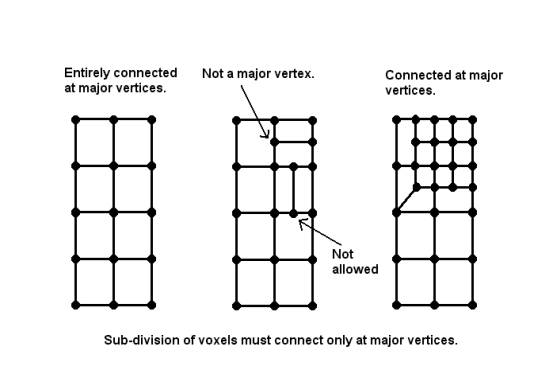

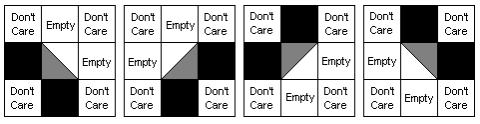

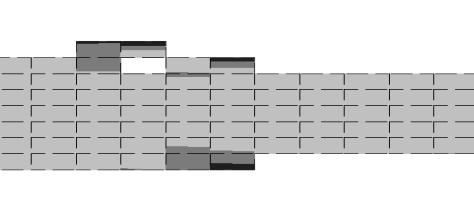

seen in Figure 2.2.

Figure 2.2

One

further issue was of concern at the beginning of the experimental work

described here; what would be the best way of getting Ansys 5.3, a commercial,

stand-alone, GUI driven FE package, to perform the analysis of the GA produced

voxel shape representations? This was a

particularly worrying problem as all of the work was performed on PC compatible

machines, which are not noted for the flexibility of their inter-process

communications systems.

These problems and their

solutions are described in detail in Chapter Three for the beam and Chapter

Four for the annulus optimisation.

2.2 The

genetic algorithm.

`Genetic Algorithm’ is the

term which has come to cover the use of evolutionary directed algorithms for

searching complex parameter spaces to find a near-optimal solution. This technique requires the formulation of a

suitable `fitness’ function which can evaluate any solution possible within the

representation chosen and return a valid fitness score. The search is performed by maintaining a

population of potential solutions and allowing them to interbreed (crossover),

mutate and die. The selection of

survivors from one generation to the next is based on each individual’s fitness

score relative to the population as a whole, thus those individuals with better

fitness scores have a higher probability of surviving and breeding in the next

generation.

The sequence of data which

represents an individual member of the population of solutions is called a

chromosome, taking its name from the DNA sequence in humans as this whole

technique is based on an analogy to nature’s evolutionary processes. Each item of data in the chromosome is

called a gene following the same naming convention. Genes in a traditional GA are single bits, however floating point

numbers and more complicated data types have also been used [Michalewicz 92]

(pages 2-9) and [Davis 91].

Crossover is the process of

taking some genes from one `parent’ and swapping them with the genes in the

same position on the chromosome of the other parent. This has the effect of propagating short gene sequences throughout

the population and as the chromosomes are more likely to reproduce if they are

fit, only sequences which make chromosomes fitter will spread through the

population. Mutation is the method

whereby new genetic variations can enter the population and generally consists

of randomly changing the value of a small number of randomly chosen genes.

A more complete description

of the theory and implementation details of conventional genetic algorithms can

be found in [Holland 75], and [Michalewicz 92] (Chapter Five) includes details

of some of the possible modifications to the basic approach which extend the

power and capabilities of this optimisation technique.

2.2.1 Other

search techniques.

Exhaustive

search is the procedure of iteratively supplying an evaluation function with

every single parameter setting within the scope of the problem being

studied. It is impossible to do this in

a reasonable amount of time for most real-world problems due to the range and

the number of parameters which define the problem. In a voxel based representation of a beam using a two-dimensional

grid divided into 32x64 voxels, the total problem space is 2 2048!

Random search involves

iteratively trying different randomly selected parameter settings whilst always

remembering the best solution found.

For large problem spaces this is ineffective due to the small

probability of randomly choosing good parameter settings, this is especially

true when a large portion of the solution space constitutes invalid solutions

due to violations of the problem constraints.

Stochastic

hill-climbing (SHC) is an optimisation technique based on the concept of

hill-climbing. In a well-behaved

function optimisation problem, the solution space may often be visualised as a

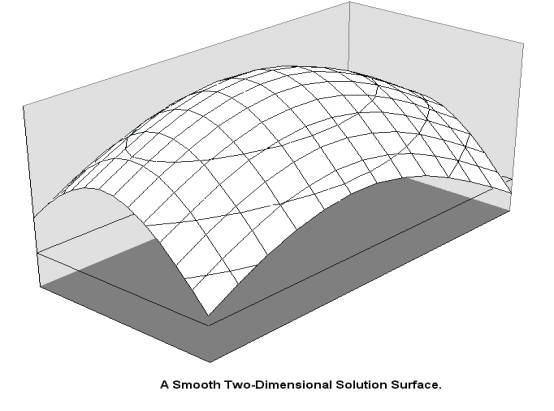

smooth surface in multiple dimensions as shown in Figure 2.3. Given a randomly selected initial parameter

setting, a steepest-ascent hill-climbing algorithm will evaluate the solution

function and find a single point on the surface. By varying the problem parameter settings and re-evaluating the

function, other points can be found which will either be worse, the same or

better than the previous solution.

Repeatedly varying the parameters and keeping the best solution from a

set as the starting point for the next iteration will result in continual

progress up the hillside, when no solution is better than the current starting

point the algorithm has achieved an optimal solution.

The type

of problem which can be solved by hill-climbing in this simplistic formulation

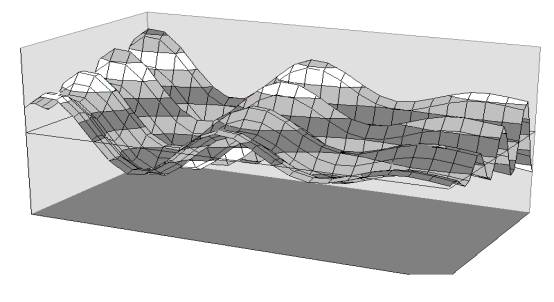

is highly limited. Most real-world

problems involve far more complex solution surfaces with many bumps and pits

which represent local optima as seen in Figure 2.4.

Figure 2.3

Uneven Solution Surfaces May Have Many Local Optima.

Figure 2.4

SHC attempts to address

these more complicated problems by adding the capability to randomly

reinitialise the current starting point when no more improvement is possible

from the position found. The best

solution found is continually recorded, so that after a given number of

iterations the SHC can report the parameter settings which produced that

solution.

A major problem with SHC is

that when a solution space with a very large number of local optima is faced,

the chance of a random re-initialisation of the parameters producing a solution

which is on the same hill as the global optima is very small. Another problem is encountered when

constraints are applied to the solution space.

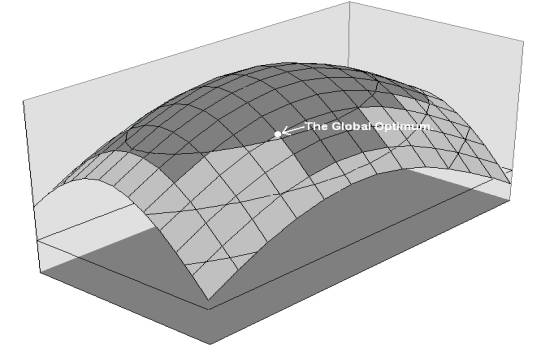

Figure 2.5 shows a very simple optimisation problem which has been

complicated by the addition of a constraint limitation. SHC can only find the optimum for this

problem if it starts somewhere on the line going straight up the hill through

it. From this it is apparent that the

probability of SHC finding a good solution is reduced drastically by the

addition of problem constraints.

Constraint Limitations Cause Difficulties For Hill Climbers.

Figure 2.5

Simulated

annealing is an approach to optimisation which comes from an analogy with the

annealing process used to toughen materials such as metals or glass. The process uses heating, followed by a

long, slow cooling period to alter the molecular structure of the materials

being treated. Similarly the

optimisation technique permits acceptance of lower quality solutions with a

probability dependent on a ‘temperature’ variable which gradually decreases

over the length of the run. This

technique is capable of escaping local minima in the search space and will

therefore find a good solution to many optimisation problems. Although it does not suffer from any of the

major drawbacks in the other techniques discussed previously, simulated annealing

does require great care in the establishment of the initial and final

temperatures and the rate of cooling.

2.2.2

Advantages of the genetic algorithm.

Genetic

Algorithms provide a good balance between exploiting the best solutions and

exploring the search space [Michalewicz 92]

(page 15) which gives them a huge advantage over random search (all

exploration) and hill climbing (all exploitation). The cross-communication of information (via cross-over operators)

within a GA [Michalewicz 92] (page 3) implies the possibility of continual

improvement over the entire search time period. This constitutes an important advantage over the random reseeding

used in SHC. GAs are also ideally

suited to parallel computation because each member of the population can be

processed simultaneously [Michalewicz 92] (page 9). This implies the ability to gain considerable processing speed

improvements through a parallel implementation of the algorithm, which is not

possible with simulated annealing as it is an iterative algorithm with

cumulative result variables.

A major advantage of the GA

is the relative ease with which new operators can be formulated and added to

the existing selection. This is

primarily due to the total separation of operators from one another. To add a new operator which directly

addresses a perceived difficulty with the optimisation is simply a matter of

designing an algorithm which will fix the problem if it is applied in a

suitable area, and will do nothing (or act to prevent the problem occurring) if

applied elsewhere. After a short period

of experimentation it is usually possible to find an appropriate probability

setting for the new operators - usually by trying settings 10 or 20 percent

apart.

This ease of design for new

operators permits incorporation of domain knowledge which can greatly increase

the search efficiency, in the same way that heuristics can improve a standard

depth-first or breadth-first search.

As the

voxel representation selected for this thesis codes directly into a very long

sequence of binary digits, the solution space is highly uneven and the problem

is very tightly constrained; Genetic Algorithms are therefore the natural

choice of search algorithm for this problem.

2.2.3 The

standard genetic algorithm.

The basic GA used as a

foundation for all of the experiments outlined in this thesis varies somewhat

from the GA described by [Holland 75].

Many of the variations were introduced to maximise the speed of

operation as it was realised that the optimisations being performed would be

very time intensive and that even small improvements in the run-time would be

useful.

The GA

overall logic is shown below in Figure 2.6 and at this level of detail the

algorithm is very similar to that included in [Michalewicz 92] as Figure

0.1.

GA control

logic

begin

initialise population

pass

¬ 0

while pass < number_of_passes do

Evaluate

population

Display

population

Select

survivors for next generation

Apply

operators to new population

pass ¬ pass + 1

end while

end

Control logic for the standard Genetic Algorithm.

Figure 2.6

Initialisation

is performed entirely by random numbers, with every gene in each chromosome

being set to either a one or a zero.

These chromosomes map directly into the voxel grid, where a one

represents the voxel is occupied and a zero indicates an empty space. After the chromosome is initialised in this

way, a connectivity check is performed and all voxels which are not connected

by a chain of active voxels to a given ‘seed point’ are set to empty space. This eliminates all of the loose or floating

voxels and can lead to an invalid chromosome if the two ‘seed points’ at the

top and bottom centre of the grid are not connected to each other - if this is

the case then the initialisation is performed again.

Evaluation

uses the stress analysis values returned from the function described in Section

2.3.1 to calculate a ‘fitness’ value for each chromosome according to the

following formula (Equation 2.1).

![]() F = V + S/(smax x 1000) + k

x max{(S - smax),0}

F = V + S/(smax x 1000) + k

x max{(S - smax),0}

where:

F = Fitness

V = Count of active voxels

S = Maximum stress of any voxel

k =

Constraint penalty multiplier

smax = The stress constraint value

The Fitness Formula.

Equation 2.1

This

formula must be minimised and can be interpreted as meaning that a greater

number of active voxels implies a higher fitness value. A larger value of maximum stress also causes

a higher fitness value (though this value will never exceed the contribution

provided by even a single extra voxel).

The rest of the formula is zero unless the stress exceeds the

constraint, at which point it will increase the fitness value by an amount

proportional to the amount by which the constraint has been broken.

The

display routine is included so that the progress of the GA can be visually

monitored as the optimisation progresses, it would also be a useful feature if

user-guided analysis was added to the capabilities of the program at a later

stage of development.

Survivor

selection is achieved through use of the Genitor

rank selection algorithm described in Section 3.3.3. This algorithm has several advantages over fitness proportionate

selection methods including the removal of the need to scale the fitness values

returned from the evaluation algorithm and the ease with which the amount of

selective pressure can be altered through variation of a single parameter. A full discussion of this approach can be

found in [Whitley 89]. The rank

selection procedure gives ‘fit’ individuals a better chance of surviving into

the next generation than unfit individuals by using the fitness values to

create an ordered list of the population and then returning randomly selected

indices to that list with a progressively higher probability towards the

‘fitter’ end of the list. It is used to

generate a new population of selected chromosomes which replaces the previous

population after the selection is complete.

The

operators used in the standard GA were two-point crossover and bitwise (or uniform) mutation [Michalewicz 92] (page

21) however the algorithm was designed to allow the addition of new operators

and the replacement of the old ones with a minimum of code alterations. Two point crossover involves randomly

choosing two ‘parent’ chromosomes, selecting any two genes at random along the

length of the chromosome and then taking the sequence of genes between those

two points and swapping it with the same gene sequence from the other

‘parent’. Bitwise mutation simply

alters the value of randomly selected genes in randomly selected chromosomes.

Unless mentioned otherwise

the GA used the standard settings described below in the experiments that

follow.

Mutation

Rate = 0.001 per bit

Crossover

Probability = 0.3 per chromosome

Population

Size = 20

Ranking

Pressure = 1.5

Chromosome

Length = 2048 bits

2.3

Introduction to shape optimisation.

A

worthwhile problem from the area of Mechanical Engineering is that of

optimising a beam to support various loads with a minimal amount of

material. Currently these optimisations

are frequently done by hand, by a person with long experience, who will then

often use a Finite Element package for stress analysis to ensure that the

resulting beam meets the various requirements.

This

section presents an introduction to the theory and mathematics required for

stress analysis, lists some previous work in the area of shape optimisation and

describes the differences between that work and the approach taken here.

2.3.1 The

stress analysis model mathematics.

A simplified stress analysis model requires very

little mathematics, is quite easy to implement and can be used to generate some

interesting results. The mathematics

for the model used in the early experiments is shown as Equation 2.2.

s = - My

I

Where:

s = total stress within a given area

M = bending moment (amount of force being

applied to the beam)

y = distance of the area from the neutral

axis of the shape

I = second moment of area

=

ò y² dA

A = size of the area being

analysed

Equation 2.2.

The neutral axis of a shape is defined as a

horizontal line which passes through the centroid of mass of the shape. As a voxel representation uses areas which

are all of uniform size and density, the centroid of mass can be found by taking

the average of the positions of all occupied voxels.

The second moment of area is approximated by

calculating Equation 2.3.

I » S (y²A)

Equation 2.3.

2.3.2 Possible approaches to shape optimisation.

There are

many possible approaches to shape optimisation problems, in this section a few

of the more common techniques will be briefly described.

The

parametric approach to shape optimisation involves creating a parameterised

model of an initial shape. Some of the

parameters can be constants, which allows the designer to apply domain

knowledge to reduce the size of the search space. Other parameters will be allowed to vary due to the optimisation

process. These are normally restricted

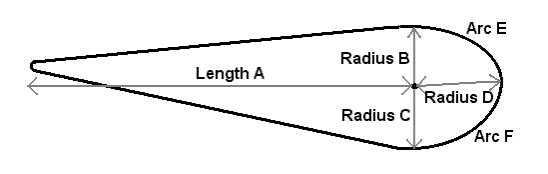

to a range, defined as the maximum and minimum values that are permitted. Figure 2.7 shows a parameterised representation

of an aircraft wing cross-section.

A Parameterised Wing Cross-Section.

Figure 2.7

The cell-growth method of

shape optimisation uses an analogy with biological cellular growth to evolve

suitable shapes. The cells are given

‘growth rules’ when they are created, and then when they develop according to

those rules the resultant shapes are evaluated for their fitness values. The growth rules are treated as chromosomes

and the search is performed using a GA to optimise the rules. Some dynamic feed-back during the growth

process is possible using a variation on this approach which involves

continually evaluating the developing shapes.

If an area is suffering from very high stress for example, then more

cells can be encouraged to grow in that area by adjusting the local growth

parameters.

Primitive building blocks

have been used by [Bentley 96] to evolve complex shapes using his Generic

Evolutionary Design system. This system

uses ‘clipped, stretched cuboids’ as the spatial partitioning representation

and a GA performs the search by modifying genotypes which represent each

individual design. This technique has

enjoyed some great successes and has been used to evolve designs for tables,

steps, heat sinks and many other components.

2.3.3 The

voxel based approach to shape optimisation.

Previous

work on shape optimisation has primarily concentrated around parametric

representations of simple machineable shapes and has produced some very useful

results [Smith 95a]. The parametric

representation, which uses a series of parameters which are varied to alter the

shape being represented, is a common choice for shape optimisation problems due

to the simplicity with which restrictions on the shapes can be

incorporated. As noted previously,

unrestricted shape optimisation representations will frequently lead to

‘breaking’ the evaluation function and so parametric representations are often

used to prevent this from happening.

This project uses a voxel

based space representation which divides the shapes being optimised into a

uniform grid of rectangles or boxes.

Each subdivision is represented by a binary value which indicates

whether the voxel is empty or full.

Similar work has been done by [Chapman et al. 94] and [Shoenauer 95] however [Chapman et al. 94] used only standard GA operators and so suffered from the

problems raised by [Watabe & Okino 93], and [Schoenauer 95] became

concerned about the size of the chromosomes required to represent detailed or

real-world problems and moved into alternative forms of problem representation.

Voxels may have any

dimensionality, however representations of more than three dimensions are not

required for the approach to shape optimisation taken here. Early experiments were performed in both one

and two dimensions in order to explore the possibilities and gain insights into

the problem area and the operation of the Genetic Algorithm.

The binary voxel

representation leads naturally to very long chromosomes and the problems

concomitant with the huge search spaces that they impose. However it also allows far more complex and

varied shapes than a parametric representation - which is limited by the user’s

choice of what aspects of the representation will be controlled through the

parameters. In particular, holes in the

material are entirely possible and even probable if there is a small low-stress

area in a high-stress region - a parametric approach can only create holes

where the user is expecting them to be required and has defined some

appropriate ‘hole-control’ parameters to represent them.

Voxels are

limited in that they can only form an approximation to a curve, however as the

number of subdivisions used is increased, the approximation becomes more

accurate and this can easily be controlled to suit the user’s accuracy

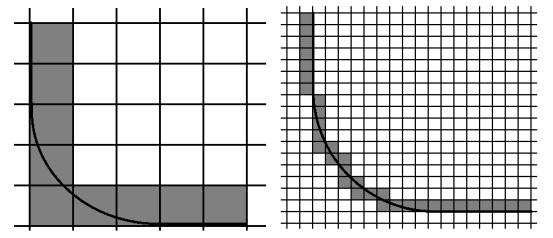

requirements (Figure 2.8). There is a

trade-off to be made in this situation however; the higher the number of

subdivisions, the longer each individual evaluation will take. Thus the user must attempt to set the level

of accuracy to be just sufficient if the amount of time taken by the analysis

is also a consideration.

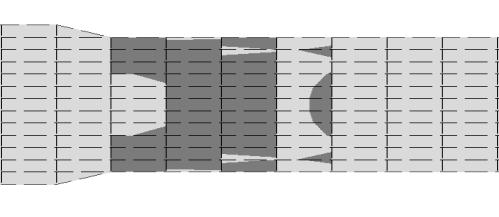

Lo-resolution Voxel Grid Hi-Resolution

Voxel Grid

Figure 2.8

2.4

Miscellaneous relevant work on GA based shape optimisation.

[Watabe & Okino 93] describe shape design and

optimisation by use of Free-Form Deformations (FFD) which use a matrix of

control points to deform a default shape.

This work includes three criticisms of a voxel based representation

method for shape optimisation problems:

n

Long

chromosomes.

n

Creation

of small holes.

n

Valid

parents don’t often make valid children.

The crossover technique used

in this work is to take a sub-set matrix of the control points and swap with

the other parent. Three sets of

experiments are described and the results are very good. The third set of experiments uses a Finite

Element Method package in an attempt to minimise mass for a given maximum

stress.

The paper: [Chapman et

al. 94] covers genetic algorithms for shape optimisation under stress

constraints. They use a one-point

crossover claiming better results than from uniform crossover, a result which

will be confirmed by the experiments detailed in Section 3.3.7. The work includes a simple rule for avoiding

isolated pixels in the final representation by requiring a level of

connectivity (4 directional) to a given ‘seed’ pixel, a concept which was

adapted to the experiments performed here and extended to require two ‘seed’

voxels, one at each end of the voxel grid.

They also assert that balancing a penalty parameter (for beams that fail

the stress constraint) is critical for obtaining good results, as too high a

penalty will produce beams that fall too far within the constraint (with the

corresponding extra material this entails).

This result is again confirmed by the experiments detailed in Section

3.3.4.

In [Bentley 96] a

description of a very powerful generic shape

optimisation tool is given. This system

uses clipped, stretched cuboids as a primitive which is used to partition space

into occupied/void areas. The results

are very impressive and the system has developed designs for a large number of

different parts and components. The

emphasis is very much on the generality of the method, and it includes a

technique which allows the user to easily specify the evaluation function from

a library of already developed evaluation programs.

2.5 Conclusions.

This

chapter has introduced the basic theories behind genetic algorithms, shape

optimisation and stress analysis, and has described the problems to be

addressed in later chapters. Previous

work in this field has tended to concentrate on parametric representations and

this has evolved good designs for aircraft wings and other components. The voxel based approaches to this problem

have also been successful with work by both [Chapman et al. 94] and [Schoenauer 95] being done on a side-view beam

topology optimisation problem with interesting results.

The rest of this thesis will

describe the investigations undertaken on two separate problems from the field

of shape optimisation using a voxel based representation and a modified GA to

perform the search.

The first investigation will deal with an

artificially simple example in order to experiment with GA operators with the

intention of designing a selection of good, new, general purpose operators that

perform well in a voxel based design space.

The second investigation is intended to take those operators and the

knowledge gained about the GA, and try to apply it to a real-world optimisation

problem.

The operators designed and

described in Chapter Three were also intended to be easily adaptable to a

three-dimensional voxel representation, however this intention has yet to be

proved.

This work will necessarily be restricted to just

these two optimisations due to time limitations, however as the investigations

have been successful, future work could extend the discoveries to virtually any

two-dimensional shape optimisation problem which can be evaluated by a FEA

package. This includes stress, loading,

heat, liquid flow and electro-magnetic field optimisations.

Chapter Three.

Design and Testing of New Operators:

The

techniques for the design of effective Genetic Algorithms are many and varied

[Holland 75][Davis 91][Michalewicz 92] and a great deal of time can be spent

adjusting parameters and trying different operators to obtain the most

effective balance between convergence on a good solution and exploration of the

problem domain. The stress analysis GA

was initially used to evolve results for simplified versions of the problem

area in order that the optimisations suggested by early results could be

investigated rapidly. The simplified

physics model of the beam’s stresses uses the mathematical approximations

described in Section 2.3.1 in order to permit rapid calculation of the fitness

of each individual in the population.

The work described in this

chapter details early experiments with a one-dimensional chromosome followed by

the extension of the experiments to two-dimensions and the subsequent GA

optimisations. A comparison is then

made between the results gained from the naïve GA and the results made possible

following the addition of new operators.

3.1 The one

dimensional experiments.

The first experiments were performed on a

one-dimensional chromosomal representation of a beam cross-section. This very simple case was chosen as the

starting point for the experiments as the expected results are well understood

[Gere & Timoshenko 84] (pages 251-261) so it permits cross-checking of

actual results gained against expected results. The programming involved in the Genetic Algorithm was not very

complicated, and neither was the implementation of the simplified stress

analysis physics model being used at this time, however it seemed reasonable to

take this opportunity to verify their operation together.

The material and force parameters used for this

initial set of runs were:

Area

Represented = 0.75m²

Maximum

Stress Allowed = 100 000 000 Pa (Steel)

Bending

Moment = 200 000 Nm (Force applied)

The GA used settings of:

Mutation

Rate = 0.005 (per bit)

Crossover

Probability = 0.25 (per

chromosome)

Population

Size = 60

Ranking

Pressure = 3

Chromosome

Length = 64 bits

The

mutation operator was the standard uniform

mutation [Michalewicz 94] which flips bits in the chromosomes with each bit

having an equal probability of being altered.

The crossover operator used was also standard; the uniform crossover

[Michalewicz 94] gives every bit in one parent’s chromosome a set probability

of being swapped with the corresponding bit from the other parent. The GA used a roulette wheel selection mechanism with standard ranking (refer to [Whitley 89] for a good description of

the most common selection mechanisms and their influence on diversity and

convergence). An elitist

mechanism was also implemented whereby the best solution found in any

generation was guaranteed to survive unaltered into the next generation.

The

fitness function described in Chapter Two as Equation 2.1 was designed to

minimise the area of the beam cross-section (number of active voxels) whilst

remaining capable of withstanding the maximum allowed stress, with a penalty

value being applied to any solution which broke that strength constraint. A small additional factor was included in

the fitness calculation based upon the maximum stress point in the beam. This has the effect of causing the valid

solutions to continue to evolve towards the best possible solution (in this

case a beam which minimises area and

minimises the maximum amount of stress present).

A valid

solution for this simplified model of the physics is any shape which does not

exceed the maximum stress constraint, and the best solution would be the shape

with minimal mass and the lowest value for its’ maximum stress point. For the purpose of this one-dimensional test

virtually any shape at all will be valid.

The row labelled `solution’ in Table 3.1 represents the number of

generations taken to find a valid solution with the minimum required mass (mass-optimal).

Categories of solutions.

Figure 3.1

The best possible solution for this simple problem

has all of the mass evenly divided with as much separation between the two

areas as possible. By looking at the

stress analysis equations in Section 2.3.1 it is clear that the further apart

the two stress bearing components are, the lower the maximum stress encountered

in the beam will be.

Ten trials

of this program produced the results shown in Table 3.1. In each case a mass-optimal solution was

found rapidly and then evolution continued towards the expected best solution

for this problem (though it rarely found that solution during the period of the

trial). Each trial was allowed to

continue for 1000 generations (1000 Generations x 60 Population = 60000

Evaluations).

Trial |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

|

Solution |

134 |

140 |

163 |

114 |

121 |

153 |

108 |

231 |

121 |

119 |

|

Best |

- |

- |

- |

464 |

- |

- |

- |

905 |

- |

- |

Number of generations required to find solutions.

Table 3.1

These

results show a mass-optimal solution being found after an average of 8424

evaluations, followed by a highly variable amount of time spent searching for

the best possible solution. This is the

type of behaviour expected from a Genetic Algorithm with a strong selection

pressure for mass reduction and a much lower emphasis on optimality.

To confirm

that the stress analysis mathematics was correctly implemented, the result of

this particular problem was calculated independently, assuming that an ‘I’ beam

is the best solution. For a steel beam

0.5m high the expected value for the second moment of area is approximately

0.001m4. Inspection of the

variables generated by the stress analysis routine revealed a value of 0.00145m4

for the fittest member of the population when the chromosome represented a beam

0.516m high. This result indicates that

the second moment of area is being calculated correctly and from this and

Equation 2.2 it is clear that the stress calculations must also be correct.

Having

determined that the GA and the mathematics involved in the stress analysis

fitness function both work as desired, the experiments progressed to a more

complex treatment of the problem; the representation of the beam cross-section

was expanded to include two dimensions, vertical and horizontal.

3.2 A

two-dimensional representation of a beam cross-section.

The

one-dimensional representation was incapable of representing a complete ‘I’

beam and so made do with representing the top and bottom surfaces, omitting the

vertical web from the calculations

entirely. The two-dimensional

representation is theoretically capable of representing the web, however the

additional mathematics required to simulate the vertical and horizontal forces

and calculate the stresses which necessitate the existence of a web are

sufficiently complex that it would require the use of a finite-element method

package. In order to maintain the

advantages to optimisation available from extremely fast evaluations, it was

decided to continue to use the same simplistic model of the physical forces

applied to the one-dimensional problem and to treat the consequent absence of a

properly designed web as an unavoidable side-effect.

The code

modifications required to extend the beam cross-sectional representation to two

dimensions were minor because the original representation was already dealing

with the width of the beam, although as a single binary parameter which

represented a whole line. The new

representation used was a two-dimensional array of binary cells, a change that

required the addition of an x component to the calculations finding the centroid

of the shape. This simple change

increased the size of the chromosomes from 64 bits to 32 x 64 = 2048 bits,

creating a search space of 22048 which is extremely large even for a

GA.

Large

search spaces can prove problematical for all forms of search unless they have

an extremely simple solution space, for example: A problem with only a single well-defined optimum can be searched

easily by even a simple technique such as hill-climbing. However most real-world problems are far

more complicated than this and consequently increasing the size of the search

area decreases the probability of the global optimum being found.

3.3 The GA experiments.

The

following experiments were intended to improve the performance of the GA on a

reasonably simple two-dimensional beam analysis problem in order that the

optimisations discovered would be available for the more complex real-world

analysis detailed in Chapter Four of this thesis. To try to ensure that the alterations and improvements made to

the GA here will also prove beneficial to the real-world problem, it was

decided not to concentrate on fine-tuning any of the various parameters

available but rather to focus on the design and operation of various new

operators. Parametric variations were

restricted to an absolute minimum and were used only to determine the

approximate values required to gain reasonable advantages from the new

operators.

In the

following experiments the following parameter settings remain constant unless

mentioned otherwise:

Beam

Dimensions = 0.05 x 0.10 metres

Bending

Moment = 13000 Newton

Young’s

Modulus = 2.0e8 Pascal

Voxel Grid = 32 x 64 voxels

3.3.1 Experiments using the naïve GA.

The first

set of experiments with a 2D representation treated the chromosome as a long

one-dimensional binary string which wrapped around at the vertical edges onto

new lines to form the two-dimensional cross-section. The GA used a standard two-point

crossover operator and the uniform

mutation operator described in Section 2.2.3.

It used settings of:

Mutation

Rate = 0.001 (per bit)

Crossover

Probability = 0.35 (per

chromosome)

Population

Size = 20

Ranking

Pressure = 3

Chromosome

Length = 2048 bits

3.3.2 Results obtained from the naïve GA.

With this

particular optimisation problem, the difficulty lay not in getting a valid

solution, as even a solid beam will satisfy that requirement, but in getting a

near optimal-mass solution. The first

experiments were relatively unsuccessful in this regard, despite showing a

tendency to evolve towards the same known best case found in the 1D trials, the

results after 2000 generations were full of small holes and had extremely

uneven inner edges. This can be seen in

the typical end-of-run results shown in Figure 3.2 (the numbers represent the

fitness values of each individual).

Typical End of Run Results From the Naïve Ga

Figure 3.2

The stresses were

concentrated at the vertical extremes of the beam, so the material in the

middle contributes less towards the total maximum stress that the beam can

withstand than the material at the top and bottom. The GA even in this simple standard form rapidly removed material

from the middle of the cross-section, and in the later stages of the

experiments was observed to be moving material from low stress areas into high

stress areas where holes were left near the extremities. However this first naïve GA approach took an

extremely large number of evaluations in order to make significant progress,

and this is not acceptable as later experiments will have a greatly increased

evaluation time when the FE package is integrated. The rate of improvement was also seen to decrease as the run

continued, levelling off to almost none at all by the end of the run. This means that the GA was not finding any

further improvements to the chromosome, and as the results are visibly poor it

indicates a general weakness in the operators being applied.

Figure 3.3 shows a graph of

fitness values versus generation number for a typical selection of three of the

ten trials performed with this program.

The horizontal axis represents the generation number at which the

results were found and the vertical axis represents the fitness values. Fitness values should be minimised for this

optimisation, so the lower the fitness value, the better the quality of that

individual solution.

The steepness of the curve

during the first two hundred generations indicates that improvements were being

made rapidly during this period, but as the optimisation approached the

five-hundredth generation the rate of progress had diminished

considerably. This effect was expected

as the GA will rapidly find most of the obvious optimisations available and

then the search will have to work harder to find any further worthwhile

improvements. The problem with these

results was that the naïve GA levelled off too early; the quality of solution at the end of the trial indicates that

there were still many improvements to be made but the rate of improvement

visible on the graph is almost zero.

Further work detailed in

this chapter was therefore concentrated towards improving the operators and

parameter settings for the GA, in order to achieve greater benefits during the

early search period, and to produce better quality final results.

3.3.3

Experiments with the rank selection pressure.

This

experiment was intended to discover the effect of changing the rank selection

pressure variable used in the Genitor-type ranking algorithm [Whitley 89]. The pressure variable controls the

proportional selection from the population based on the fitness ranked position

within that population. A selection

pressure of 1.0 results in a totally random selection (all members have equal

probability of being selected), and higher selection pressures result in

increasing probability that the fittest members of the population will be

selected. The Genitor paper suggests

that 1.5 is a suitable value to be used for many experiments, producing a good

balance between population diversity and the rate of fitness improvements.

Implementation

of the algorithm is exactly as given in the Genitor paper*

:

linear_selection( pressure : float )

index = Population_size *

(pressure - Ö (pressure2 - 4 * (pressure - 1) * random(1.0) ) ) / 2 / (pressure - 1)

The Genitor Linear_Selection() Function.

Figure 3.4

The

population is sorted by its fitness values using a linked-list bubble-sort

algorithm before the Genitor selection procedure is invoked, thus the result of

the linear_selection() routine is an index to the linked-list, which in turn

holds the position of the selected individual in the population.

The

survivors selection procedure is simply to invoke this procedure once for every

member of the population, each time copying the selected member of the old

population into consecutive elements of the new population array.

The

Genetic Algorithm used to perform the searches was the same as described in

Section 2.2.3: ten trials were executed

and the number of iterations per trial was set to 2000.

Figure 3.5

is a plot of the fitness of the best individual from the population averaged

over all ten trial runs (on the vertical axis) against the generation number

(on the horizontal axis). It shows the

full set of results and clearly indicates that at selection pressures of 1.1 and

even 1.3, there is insufficient differentiation between the poor members of the

population and the fit ones. This

results in chromosomes which violate the problem’s constraints being selected

frequently enough to significantly degrade the average results. The large steps visible in both of these

lines are caused by selection of individuals who are extremely unfit due to

large constraint penalties being applied.

Figure 3.6

is a more detailed examination of the 1.3, 1.5, 1.7 and 1.9 selection pressures

in which we see the expected results of higher pressures producing steeper

fitness curves but ultimately resulting in similar overall fitness levels after

40000 evaluations. The 1.5 line is very

slow to converge with the 1.7 and 1.9 lines, indicating that it takes

significantly longer before it produces solutions of equivalent quality.

The very

low selection values do not appear to cause enough selection pressure to avoid

repeated constraint violations, although this may be affected by adjusting the

Constraint Penalty Multiplier. The

lower selection values also result in a slightly worse result after 2000

generations. As a consequence of these

trials further experiments will be performed using a rank selection pressure of

1.7, as the suggested 1.5 is too close to the border-line where the constraints

are being violated regularly and it also does not converge rapidly enough to

the better solutions found at higher rank pressure levels.

3.3.4

Experiments with the constraint penalty multiplier.

The purpose of these

experiments was to investigate the effects of changing the constraint penalty

multiplier k used in the fitness

function (Equation 2.1), and to find an appropriate value for this variable

which maximises the search capabilities whilst avoiding an excess of non-viable

solutions. The constraint penalty

multiplier (hereafter referred to as the penalty value) is applied to the

fitness value of any chromosome which has a maximum stress value greater than

the constraint level, this will lower the relative fitness of that chromosome

reducing it’s probability of survival into the next generation.

The

penalty value is multiplied by the amount of stress which exceeds the stress

constraint, so the effect on a chromosome’s fitness depends on the degree to

which it is non-viable. This approach

permits chromosomes which are only slightly over the constraint limit to

survive for a while, thus increasing the population diversity at and around the

stress constraint level.

The

Genetic Algorithm used was as described in Section 2.2.3 except that the

vertical web which runs through the

middle of the ‘I’ beam was enforced after the operators were applied and before

the evaluation function was called.

Enforcing the web avoids the complicating issue of the amount of mass

added by the web itself. A crooked web

would contain more mass than a straight one, but the simple model of the

physics being used for the evaluation stage does not contain any forces that

would encourage a straight web. Rather

than try to factor out the effect that the different randomly evolving webs

would have on the final fitness values, it was considered to be more sensible

to avoid the issue entirely in this way.

A population size of 20 and

an initial run length of 1500 generations was used. The optimisation was

performed ten times with each of the penalty values 1E-3, 5E-4, 1E-4, 5E-5 and

1E-5. Other parameters were set as

follows:

Beam dimensions = 0.05m x 0.10m

Bending moment = 13000 Newton

Voxel grid size = 32 x 64 voxels

Crossover probability = 0.3 (per chromosome)

Mutation probability = 0.001 (per gene)

Rank selection pressure = 1.7

Stress constraint = 2.0e8 Pascal

The web was enforced.

The first

results graph (Figure 3.7) for these trials shows a plot of the average fitness

of the best individual from the population over the ten trials against the

generation number. This graph is

somewhat misleading as it indicates that as the penalty value is reduced the

average fitness of the population tends to improve, unfortunately this is at

the cost of increasingly poor solutions.

What is not clear from this graph alone is that most of the fittest

individuals at the lower penalty values are non-viable in that they break the

constraint limit - often by a considerable amount.

The second graph (Figure

3.8) shows the maximum stress level of the best individual from the population

averaged over the ten trials against the generation number, the stress limit

constraint is marked as a horizontal line for reference. This graph clearly shows the difficulty with

the lower penalty values - the data for 1E-5 is almost entirely above the

constraint limit meaning that the majority of the solutions from the population

were non-viable.

To be able to see the

results for the 1E-3 and 1E-4 penalty values a considerable expansion of scale

is required, Figure 3.9 shows the data from Figure 3.8 expanded about the

constraint limit line (which is again included in the graph). Here even though the Maximum Stress average

is very noisy data, we can see that the higher penalty values cause maximum

stress to be further below the constraint limit than the lower penalties. The average for the penalty value 1E-4

actually crosses the constraint limit several times, but always returns to

viable solutions after a short while.

Higher

penalty values prevent recurrent violation of the stress constraint, but very

high penalties reduce the available search space by forcing solutions to stay

further within the limits. Even in the

long trials the higher penalty values have this restrictive effect. This is in keeping with the results found by

[Chapman et al. 94].

As the standard genetic

algorithm verifies the viability of the initial population by using the fitness

evaluation function (which incorporates the penalty value), the

fitness/generation curves do not start at the same place for different trials

but instead indicate that a lower average initial fitness can be achieved by

using lower penalty values. This effect

can be extremely useful, as a more fit initial population reduces the length of

search required in order to achieve a given quality of result.

An ideal constraint penalty

would allow the search to utilise the possibilities beyond the constraint limit

at the beginning of the search and would cause more solutions to be valid as

the search progresses towards it’s conclusion.

This would encourage a fitter starting population, allow maximum

population diversity initially and ensure that the eventual result population

contains useful solutions.

These results suggest that a

dynamically varying penalty value may result in more rapid optimisation in the

early stages of the search whilst avoiding the problem of non-viable final

solutions. This possibility was

investigated and the results are included in the next section.

3.3.5

Experiments with a dynamically changing constraint penalty multiplier.

These

experiments investigate the efficiency of using a dynamically changing

constraint penalty multiplier rather than the static values used in the

previous set of experiments. The

rationale for this approach is that it may be good for the search if it is

allowed to break the constraints during the early stages of the optimisation,

but that the results at the end of the run must

contain viable solutions.

The

constraint penalty multiplier must start off low and increase as the

optimisation continues, therefore the generation number will be used as the

variable which controls the function:

f(generation) = constraint

penalty multiplier

Equation 3.1

A linear

function could be used to test this approach, however it is apparent that not

only should the optimisation end with viable solutions, it should spend some

time optimising the viable solutions before the end of the run. A more suitable curve function is:

constraint penalty

multiplier = constraint base * ( 1.0 -

e (- alpha * n) )

where n is

the generation number.

Equation 3.2

This can

be seen for several values of (alpha*n) in Figure 3.10 which shows the

constraint penalty multiplier for each generation to fifteen hundred. The function describes a smooth curve from

zero to a maximum, which is a proportion of the constraint base value

determined by the value of alpha*n used.

A higher value of alpha*n makes the curve more pronounced and results in

a higher proportion of the constraint base value at the final generation.

The

Genetic Algorithm used was as described in Section 2.2.3 with a population size

of 20 and an initial run length of 1500 generations. The optimisation was performed ten times with each of the alpha*n

values 0.5, 0.75, 1.0, 2.0 and 3.0.

The graph

(Figure 3.11) shows the average fitness over ten trials for each of the tested

alpha*n values plotted against the generation number. This graph shows the effect of very low constraint penalty

multipliers in the first half of the run;

the fitness curves go up from reasonable starting values to very poor

results during the first four hundred generations, peaking at various points

depending on the alpha*n value being used.

It can be seen that the higher alpha*n values result in worse early

results, but better results later on in the run, although the alpha*n = 0.75

line is anomalous in that it leads to a better final result than the 1.0 line.

The reason for the poor

fitness values early in the run from higher alpha*n values is that the

constraint penalty multiplier increases faster for the higher alpha*n values,

thus the solutions are being penalised more strongly than those with lower

values. The better final results appear

to be due to the rapidly increasing penalty multiplier values forcing the

search into a viable search space earlier, thereby giving the search more time

to do fine-tuning on the final solution.

Comparing

the fitness graph results with the data in Figure 3.12 which shows the maximum

stress values over the same time period leads to some further insights into the

behaviour of the fitness curves. The

lower values of alpha*n lead to greater violations of the stress limit

constraint, to the point where alpha*n = 0.5 doesn’t produce any viable

solutions at all during the 1500 generations.

Typically the higher values lead to viable solutions sooner, with the

exception of alpha*n = 1.0 which takes longer to descend than alpha*n = 0.75. This can be seen more clearly in Figure 3.13

which shows a detailed view of the second half of the optimisation period and

indicates that at alpha*n = 1.0 there were no viable solutions produced during

the run.

Figure

3.13 shows that once the solutions enter the viable region by descending below

the stress limit they rarely exceed that limit again, and indeed tend to remain

at a fairly constant distance from the limit.

This is possibly due to the constraint penalty multiplier value which,

by continuing to increase, makes it less and less likely that a non-viable

solution will be more fit than a viable one.

The fitness values at the

end of the optimisation are not very much different than those obtained for

good constant values for the constraint penalty multiplier. Table 3.2 contains the end of run fitness

values for both constant penalty multipliers and the dynamic penalty

multipliers, entries followed by a * are invalid solutions which exceeded the

constraint penalty at the end of the run.

Constant constraint penalty multiplier values:

|

0.001 |

0.0005 |

0.0001 |

0.00005 |

0.00001 |

|

925.999 |

916.599 |

919.843 |

908.123 |

861.650 * |

Dynamic constraint penalty alpha*n values:

|

0.5 |

0.75 |

1.0 |

2.0 |

3.0 |

|

1004.231 * |

936.266 |

957.609 * |

932.259 |

924.466 |

End of Run Values for Average Fitness.

Table 3.2

The intention of this

approach was to allow maximum population diversity initially, but ensure that

the eventual resultant population contains viable solutions, and in this regard

the concept appears to be successful.

As long as the alpha*n value is set to ensure a suitable constraint

penalty multiplier value at the end of a run, the prevalence of invalid

solutions in the early stages of the optimisation is not a problem for the type

of problem being addressed here. This

technique is obviously not suitable for optimisations of uncertain length or

when the optimisation may be stopped before convergence and a viable solution

will be required.

The fitness curve graph

(Figure 3.11) shows that the eventual fitness of the best individuals varies

very little, which indicates that the precise setting of the alpha*n value is

not critical. However the evidence of

both the fitness curves and the maximum stress curves is that a high value of

alpha*n is better for the search, resulting in better final solutions and

avoiding the danger of non-viable populations by a larger margin. Further experiments which use dynamically

varying constraint penalty multipliers would have used an alpha*n value of 2.0,

however, as it can be seen from the Table 3.2, the constant constraint penalty

multipliers consistently perform better than the dynamic ones, therefore constant

constraint penalty multipliers were used during the following experiments.

3.3.6 A new

operator : smoothing.

The

smoothing operator experiments were an attempt to directly address some of the

weaknesses of the voxel representation by devising a new specialised operator

which should aid the search by reducing the number of small holes and ragged

edges produced by the GA. The new

operator was intended to be capable of easy expansion from two-dimensions to

n-dimensions in order that it would continue to be useful in the case of three-

(or more) dimensional problems using the voxel representation. This would be an important issue for shape

optimisations which are not capable of being represented by a simple

cross-section, for example if a beam was to have a varying cross-section along

its entire length then it would be necessary to represent it using

three-dimensional voxels.

The GA

parameters used were the same as the standard GA described in Section 2.2.3 and

the new operator was applied in addition